Our Knitting Section

Yarn – Yarn is the most important and primary requirement to make the fabric look the best and feel perfect. We choose the best long staple cotton super combed yarn from the selected mills.

Knitting - Malar Export utilizes the latest and advanced technology machineries to knit the fabrics like Reiter, Mayer & Cie to produce various qualities of circular knitted & Jacquard Fabric fabrics right from 100gsm to 400gsm. Below are the few of fabrics that we handle :

- Single Jersey Stripped Fabrics

- Durby, Waffle and Short Back RIB Fabric

- Interlock Auto Stripper Fabrics

- Interlock Jacquard Fabrics

Our Dyeing Section

Dyeing & Wet Processing – Ultra modern soft flow machines are used for fabric dyeing. Dyes and chemicals used are azo free as per Oeko Tex standards and HTHP machines used for cotton, polyester, Viscose and other blend fabrics

Garment dyeing – Garments are processed in electronically controlled garment dyeing units. This gives perfect dyeing, vintage look and wash effects. Same machines are used to produce following special effects Anti microbial, wrinkle resist, stone & sand wash, bio & enzyme wash, acid wash…

Environment – Social responsible to protect, conserve nature and in turns supports several eco friendly process and procedures that do not harm its immediate environment.

Our Production Section

We have total vertical setup 2 own units. Our sewing units is about 25,000 Sq.ft. of floor area with 150 Latest garment sewing machine, needle detectors and other sewing related machines which has been imported from major companies such Juki, Pegasus, Siruba, Brother, Etc.

The garment division with modernized machines ensure bulk production of garments like :

- T-shirts and Polo T-Shirts

- Hoodies, Trackpants and Vest

- Night Shirts and Pyjamas

- Leggings and Shorts

Our Embroidery Section

We use sophisticated embroidery divisions includes Japanese leading embroidery machines which provides hi-definition stitches in designs and enable mass scale execution with upto 9 colors.

Types of Embroidery that we do :

- Applique embroidery

- Basic Embroidery

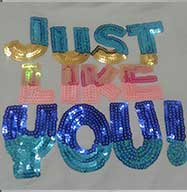

- Sequance embroidery

- chenille embroidery

| Machine make | Barudan |

| No of Machinery in our cluster | 2 |

| Colors | Upto 9 |

| Production Capacity | 3000 pcs / day |

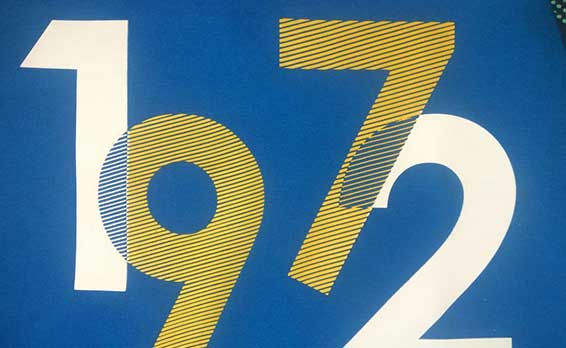

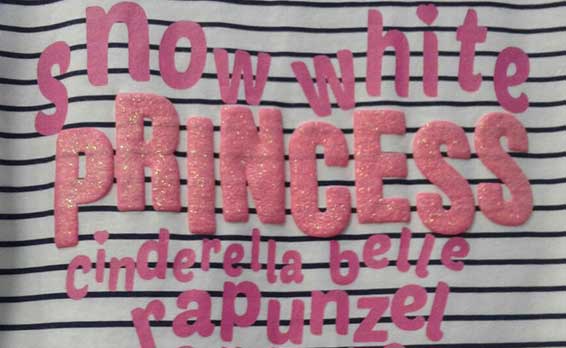

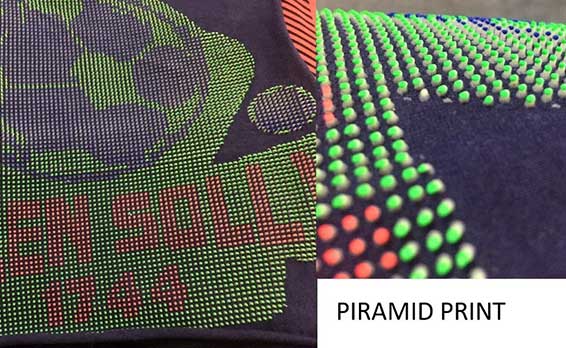

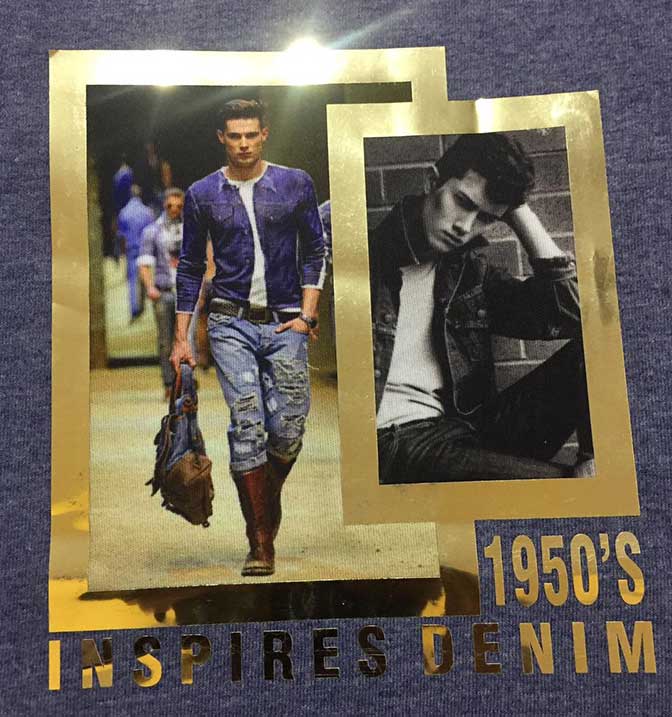

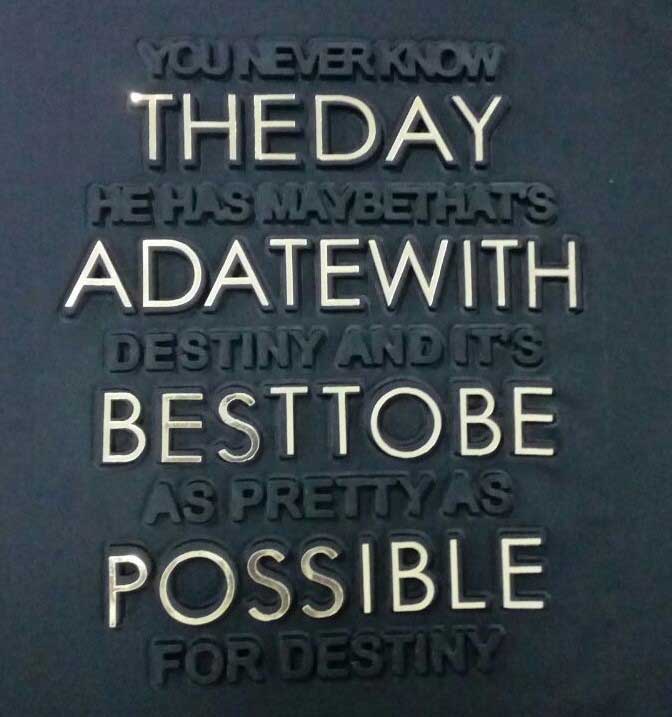

Sample Works

Sample Works

Our Printing Section

We use a garment printing division equipped with automatic screen printing machines MHM and M & R and manual machines includes capacity of 40,000 impressions with average of 15,000-20,000 garments per day. We have well experience in printing techniques and we are doing Discharge, Pigment, Gadi, Hi-density, Foil, Flock, Glitter, Gel and Puff prints up to 10 colors.

| Machine make | MHM Printing Machine |

| No of Machine | 2 |

| Colors | 8 to 12 |

| Types of Prints | Discharge Print ,Reactive Print, Khadi Print (White Ink Print), Dry Discharge Print, Gel Print, Night Glow Print, Water Mark Print, Water Base Pigment Print, Oil Base Pigment Print and Cotton Burn out Print |

| Production Capacity | 5000 pcs / day |